The Genetic Supply Chain – It Takes Time

The definition of supply chain is “the entire network of departments or companies, directly or indirectly interlinked and interdependent in serving the same customer or group of customers”. In simple terms, is all of the steps in the process of developing and producing a product and getting that product to the customer. It is a value chain process, because without it we do not have the ability to give our customers/growers the poults they want, when and where they want them.

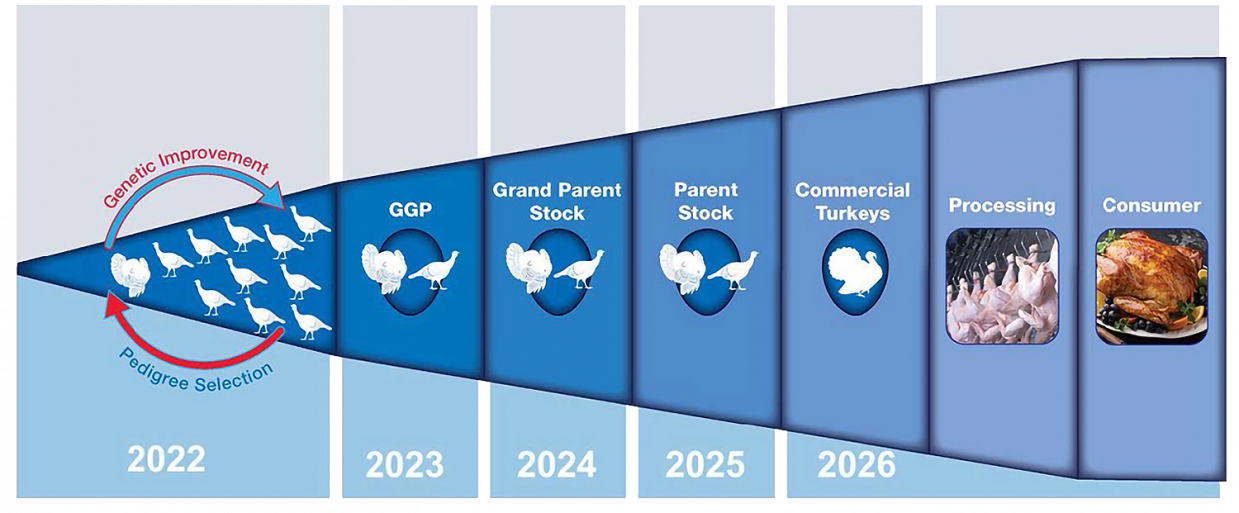

The supply chain in the turkey industry is also known as “the Pipeline”. The Pipeline is a process by which primary breeders spin off genetic improvements into a multiplication system that requires four years to reach the consumer (figure 1). The pipeline permits the genetics of populations called pedigree to pass their genes to great-grandparents (GGP), who pass their genes to grandparents (GP), who pass their genes to parent stock (PS), who pass their genes to commercial poults which are the turkeys we consume. The Pipeline is interdependent and interlinked in a multiplication process that is very efficient and any disruption or mismanagement in the chain delays the genetic progress. One pedigree mating is responsible for 21,000 tons of white meat from male commercial turkeys.

Figure 1. The Genetic Pipeline: Every generation is a one-year progress

Figure 1. The Genetic Pipeline: Every generation is a one-year progress

Investing in the Parent Stock Segment

Historically, primary breeders sold parent stock to integrators and to multipliers. This parent stock segment of the Pipeline saw little investment in infra-structure for many years. There were many small poult producers focused on low cost production and they did not generate the resources to invest in hatcheries and farms. This model was not sustainable and through the years, almost all of the companies (hatcheries) in Figure 2 were either sold or merged.

Figure 2. Past Poult Producers

Over 10 years ago, Aviagen entered the parent stock multiplication segment of the Pipeline by building the first modern hatchery in Osceola, Iowa. This hatchery was the beginning of an investment strategy to build a new level of biosecurity and diversify the production risk into this important segment of the pipeline. Since that time, Select Genetics built a second hatchery in Terre Haute, Indiana and on February 29, 2024 we broke ground for a third hatchery in Goldsboro, North Carolina. We expect this hatchery to be operational in spring of 2026. We’ve also built new farms and broadened our regionalization strategy. This is not the most efficient production strategy but we feel it is important to have farms in multiple regions to spread risk. This way if there is a disease issue in one region, it is a smaller percentage of our production, helping to ensure we can still supply our customers.

An advantage of being in the parent stock segment of the industry is that it provides a direct route for genetic progress to flow down the Pipeline to our customers. We can implement higher selection pressure at the parent stock level and in some cases GGP or GP toms are moved from Aviagen’s primary breeding program to the parent stock farms to speed the genetics progress. This could not have been done without entering this segment of the Pipeline.

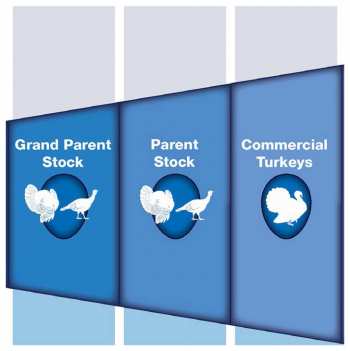

Figure 3. From Grand Parents to Commercial Turkeys

Even with this direct flow, each segment of the Pipeline is a one- year generation. This requires planning for each segment a year in advance. It is critical that we plan our placements carefully to ensure proper utilization at each generation. As shown in Figure 3, Aviagen Turkeys is placing Grand Parent Stock in 2024 for Select Genetics placements in 2025. In turn, Select Genetics is placing Parent Stock for commercial poult orders in 2026. That is why it is so important to have our commercial volumes at least two years out.

The Genetic Farm Flow

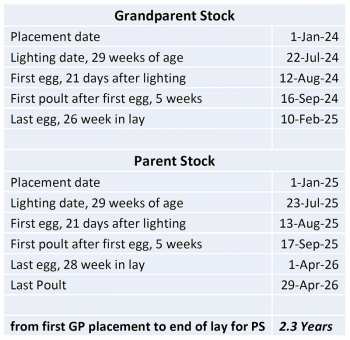

Many of us in the breeding business are used to looking at an excel file that details the farm flow for years from GP poult placement to commercial poult production. The following are the basics for a generation:

- It takes 29 weeks to light a hen.

- It takes about 18 to 21 days to lay the first egg after lighting.

- We lay the flocks for 26 to 28 weeks.

Figure 4 below is a simplified flow: if we place a GP flock in January 2024 it will produce its first PS poult in September 2024. That PS flock will produce its first commercial poult in September 2025 and to finish lay it will be April 2026. This is over 2 years interlinked supply chain process.

Figure 4. Simple Farm Flow Timeline

Summary

In turkey breeding, utilization is critical for financially viability and to ensure genetic progress is moving through the pipeline without disruption. It would be risky and expensive to place a GP or a PS flock without knowing where the poults will be sold and placed. It is over a two-year pipeline and there are no short cuts, so we place GP and PS flocks based on contracted orders two years out. If we do not have contracted orders like any business, it is not wise to plan to produce the poults. This is why we encourage all growers to have a contract for the next two years to protect their poult supply.